Szp Group Chain

our products

-

Transmission and gear parts 5 products/services available

-

Roller chain 3 products/services available

-

Conveyor chain 6 products/services available

-

Bicycles, bicycle parts and accessories 2 products/services available

-

coupling 20 products/services available

- Industrial coupling

- Dotting the coupling

- Spiderflex coupling

- Pinflex coupling

- Crown pin coupling

- Tyreflex coupling

- Disc coupling

- Chainflex coupling

- Heavy-duty all-metal coupling

- Hydrastart coupling

- Spiderjaw and Spiderwrap connectors

- Renoldflex coupling

- High temperature blind coupling

- DCB GS coupling

- Frequency conversion coupling

- Public transportation coupling

- Universal joint coupling

- Standard gear coupling

- Flexible disc coupling

- Pin and bushing coupling

-

clutch 11 products/services available

-

Material handling machines and systems 1 products/services available

-

Elevator accessories 1 products/services available

-

zipper 1 products/services available

-

Fixtures and clamping equipment 1 products/services available

-

adapter 1 products/services available

-

Buckets, tanks and containers 1 products/services available

-

Pumping unit 1 products/services available

-

Separator and filter 2 products/services available

-

Bulk Bag Loader 1 products/services available

-

Conveyor components 2 products/services available

-

other products 12 Available products

Other products/services

We provide a complete chain pin extractor, standard accessories, Renolube escalator chain, wastewater treatment chain and theme park trident chain product series

Chain pin extractor

renold's chain pin extractor is a quick and easy way to cut chains.Cutting a wedge-shaped riveting chain means that the pin head must be ground off, and then the pin must be hammered through the board.This is too time-consuming and energy-consuming. The renold brand and renold Synergy drive chains have end softening pins with rotating or round rivets.You can cut the chain by hand at any time without messing up.Renault makes everything easy!Order your chain pin extractor now!

Standard accessories

Standard accessories are components installed on the base chain to make it suitable for specific purposes as conveying media.Accessories can form an integral part of the chain plate, or they can be built into the chain as a substitute for ordinary chain links.Other accessories (depending on the type) are fixed on one or both sides of the chain plate by projection welding or fillet welding.The standard attachments are described as follows: F attachment outer link or inner link F attachment provides a flat surface at right angles to the chain plate.They are used to fix push rods, scrapers, etc. K attachment outer link or inner link K attachment provides a platform parallel to the chain line and the bearing pin.They are used to fix slats, scrapers, buckets, etc. to the chain. L attachment L attachment is integrated with the chain outer plate.Usually they have one or two holes (L2 is preferred), but for squeegee applications, they can be provided with no holes and various box widths (LO type).The outer rollers used for the outer rollers of the hollow bearing pin chain have two main advantages: As a direct load carrier, they enable the chain rollers to be used only for gear transmission, and they can be easily replaced in the event of wear of the outer rollers Without changing the chain.They are especially useful when accessories prevent the gear rollers from running on the support track in the return stroke or when the roller load is high.The bolts and the chain plate bolts with holes can be assembled by hollow bearing pins or chain plates, and are fixed by nuts and spring washers.Single holes are mainly used with bolts and are required on both sides of the chain.Double holes are used to assemble special accessories on one or both sides of the chain.The holes on the inner plate are countersunk heads on the inner surface to prevent the bolt heads from soiling the sprocket teeth.

Renolube escalator chain

The Renolube escalator chain is the result of extensive prototype testing in difficult applications, designed to meet the industry's growing demand for reduced service costs and longer service life. Szp Group has more than 50 years of experience and is recognized as one of the world's leading escalator chain manufacturers. Renolube composite polymer bushings are combined with specially designed bearing pins to ensure the longest service life.The main advantages are: Significantly reduce life cycle costs, development and field tests show that the life span exceeds 40 years.Due to the reduction of free grease lubrication, the environment is cleaner.Since there is no need for regular grease lubrication, service costs are significantly reduced.Compared with traditional lubrication chains that are prone to random failures, a stable and predictable wear rate is a feature of Renolube.Economical Renolube provides a completely cost-effective solution when replacing grease lubrication systems by significantly reducing expensive maintenance and life cycle costs. Endurance Renolube escalator chains have been proven to be extremely resistant to wear in public service environments.After installing the Renolube escalator chain, the design life of the chain exceeds 40 years, giving you peace of mind for life.Environment and safety Eliminating large amounts of lubricating oil and grease can create a cleaner and safer environment, thereby reducing the risk of fire.

Wastewater treatment chain

We have experience and can advise on installation and improvements to keep this critical operation running. Szp Group provides all professional chains and sprockets for the sedimentation tank and clarification tank of the sewage treatment plant.High-quality bar screen chains, 700 series chains, non-metallic, cast and stainless steel chains and sprockets, cast/steel hubs and UHMWPE sections made of 100% UHMWPE, all cast and/or steel structures.Fiberglass slats, laminated wood slats, UHMW wear strips, wear plates, claw clutches and wall bearings are also available.

Theme park trident chain

Szp Group has extensive experience in providing conveyor chains for theme park rides in theme parks around the world, from roller coasters to water rides.Through continuous research and development and inspection of the common causes of chain failures in corrosive environments, Szp Group has developed the Trident chain series to solve the three main failure areas in such environments: corrosion, seizure and wear.Solve the problem of corrosion due to frequent exposure to water, corrosion is usually a problem on water riding chains.To solve this problem, Szp Group developed a dual-process surface treatment to improve corrosion resistance.The zinc-based special coating provides excellent protection for the steel.Even if the coating is penetrated, the treatment continues to provide excellent corrosion resistance.Eliminating jams on the amusement equipment transfer and lifting the chain may cause bushings and pins to jam, and significantly shorten the life of the chain.Through the development of a unique polymer sleeve, metal-to-metal contact is reduced, thereby eliminating the risk of bushing and pin jamming.This also provides lubrication-free operation and eliminates the need for any lubrication ports.The development of the heavy-duty wall bushing design to reduce wear overcomes the premature wear and failure of the bushing, and in most cases, it can also be combined with the shell roller to reduce the wear of the sprocket teeth; increase the service life of the sprocket and the chain— -And reduce maintenance time and cost.Other advantages: Integral accessory design-eliminates the problem of accessory/board corrosion. It runs smoother and quieter than standard water slide chains. It runs on the same sprocket and track with standard chains.Excellent breaking load and working load* in the salt spray test. Note: The polymer sleeve is highlighted in yellow for illustration purposes. For more information about Szp Group Trident and how it can reduce the cost of theme park rides, please call us now +44 (0) 161 498 4600 or use our application form for more information.

Bus escalator drive solution

Szp Group Gears designs and manufactures a full range of heavy-duty transportation escalator drive solutions.Design options include: Compact drive The new WH series escalator drive combines the advantages of worm and helical gear transmission in a compact design, providing high efficiency, low noise and minimal maintenance. Direct Drives Slim Line Unit is installed directly on the spindle, eliminating the risk of lubrication and contamination.The traditional drive Szp Group provides traditional floor layouts designed specifically for the London, Washington, and New York subways.The dual-drive Szp Group has developed a variety of solutions that are very suitable for truss arrangements that can be configured as dual-drives.Replacement drives Szp Group produces replacement drives and transmissions for old and outdated designs.Our design capability can be redesigned according to sample parts or drawings.

Air preheater solution

Szp Group Gears designs, manufactures and services standard and customized air preheater drives.Design options include: Central-driven Szp Group central-driven air preheater design options, including worm and helical gear configurations, can be designed as a direct replacement of the original supply device, or designed according to OEM's new application specifications.The central design has a solid output shaft, which is directly installed on the main rotor shaft of APH and fixed by a shrink disk.The helical worm drive Szp Group provides a multi-input helical worm with a hollow hole output, which can be directly mounted on the drive shaft, or an optional Szp Group Hi-Tec coupling can be provided.It can be directly installed on multiple prime movers, including AC, DC or pneumatic motors.The drive can be manufactured in various sizes to fit power stations from 200 to 1200 MW.Different torque requirements depend on the size of the power station.Peripheral drive Szp Group provides options for peripheral drive air preheaters.The peripheral drive is installed at the end of the APH.It is equipped with a solid output shaft with a spur gear mounted on it, and the APH is driven by an externally mounted ring gear.The bevel gear helical gear drive Renold's bevel gear helical solution is a multi-stage design, with a choice of a solid output shaft that is vertically upward or vertically downward, and provides multiple inputs and integrated stop devices.The drive includes an independent lubrication system.They can be driven by gear pumps or electric motors, and can be equipped with separately installed gear motors for blocking.The main motor is driven by a fluid coupling for soft start.The drive can be manufactured in various sizes to fit power stations from 200 to 1200 MW.

Coal powder machine solution

Szp Group Gears has a unique replication plan that can provide interchangeable replacements for existing CE/Alstom coal pulverizers installed worldwide.Worm gears can be manufactured according to original drawings, or on-site "contour plug lifting" technology can be used to produce plugs from the original manufacturer's worm shaft using two-part epoxy putty.After hardening, the measured value of the contour plug is input into the Szp Group contour generation software to copy the original contour, so that the main worm, thread milling cutter, thread grinding wheel contour and gear hobbing tool can be manufactured. Replacement worm gear for CE coal pulverizer:

-

Worm gear size center distance

Gear ratio Rolling mill size CE rolling mill number 54.010 " 14 2 / 7 1003 48.010 " 13 3 / 7 943 18 3 / 5 863 41.010 " 17 1 / 5 803 36.010 " 13 5 / 6 753 15 1 / 5 703, 683 16 1 / 5 743, 723 30.010 " 12 2 / 5 673 14 2 / 5 663, 643 27.010 " 10 4 / 5 633 13 1 / 2 623 21.847 " 9 2 / 5 573 11 3 / 4 563, 543 13 3 / 4 533, 533A 15 523, 503

Two-lead adjustment

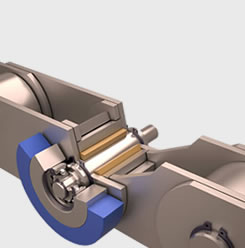

Ren-Adjust's dual-lead adjustment mechanism Szp Group Gears has introduced a new high-precision adjustment mechanism, Ren-Adjust, for dual-lead gear sets that require high-precision positioning machinery (such as turntables and machine tools).Compared to alternative systems, the new system for precise adjustment of backlash is quick and simple to operate, reducing downtime when adjustments are needed.Direct replacement of the new Ren-Adjust is designed as a simple replacement of existing machines. It can also be designated as similar components by the machine tool and turntable manufacturer. In many cases, there is no need to modify the existing design. Therefore, Renold's system does not require any redesign or modification Can replace most other manufacturers' systems.This allows OEMs to easily switch to Szp Group products, and it is equally easy for machine operators to replace existing equipment.Simple adjustment Ren-Adjust allows precise adjustment without removing the worm shaft or draining oil.It is fast and convenient to use, and minimizes the adjustment time.Adjust the backlash by simply removing the shrink disk, which will make the worm shaft move independently of the adjusting sleeve, and by turning the captive screw, the double guide worm shaft will be moved axially and the working backlash will be adjusted.Once the gap is acceptable, reapply the shrink disk. The size range of the Ren-Adjust mechanism covers a center distance of 67-500 mm.

Carter gear refurbishment

Szp Group Gears can perform a full repair of your existing Carter unit, or we can provide a fully refurbished unit from our inventory.We also provide a service exchange plan, if we can provide a discounted full refurbishment replacement in exchange for your old equipment. The Carter hydrostatic transmission has a 27:1 continuously variable transmission range and a power capacity of up to 30kW.Features and advantages Fully enclosed drive device, suitable for all harsh environments.Electronic, pneumatic or manual speed control to meet all design requirements.Accurately maintain the speed under different load conditions, suitable for all drive applications.High starting torque for all heavy machinery.Provide overload protection for mechanical safety.Dynamic breaking is the standard.Suitable for explosion-proof areas.

Vibrating screen drive

Used for continuous operation of conveyors, feeders, screening machines, packaging tables and other vibrating equipment. Long life depends on low maintenance plan. Fully enclosed gear driven eccentric wheels. 26 sizes. Renold's Ajax vibrating screen drive is recognized as energy-saving. The device is suitable for countless new and unusual application possibilities.Standard applications include: Open and closed disc conveyors, screening machines, feeding machines, packaging tables, dehydration devices, anti-disassembly machines, electronic test tables, and cable laying ploughs. There are six basic sizes, each with a variety of eccentric weight options.Force output ranges from 115 to 11 lb, operating at low frequencies.

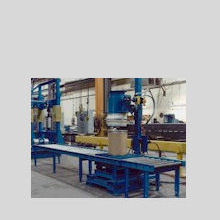

Vibration gas station

Vibrating table/baler: Renold's custom-designed vibration table/baler provides more materials in a smaller space; weighing, vibrating and filling at the same time.Each unit is designed to ensure proper vibration, thereby eliminating voids and increasing the density of materials in the bags, boxes, barrels and handbags being packaged.The density can be increased from 20% to 50% in the shortest cycle time.Auxiliary equipment, such as online roller conveyors, pallet distributors, sliding pallet distributors, etc., including various PLC interfaces, complements the workstations to form a turnkey system that meets any specifications.