Szp Group Chain

our products

-

Pumping unit 1 products/services available

-

Separator and filter 2 products/services available

-

Bulk Bag Loader 1 products/services available

-

Conveyor components 2 products/services available

-

Transmission and gear parts 5 products/services available

-

Roller chain 3 products/services available

-

Conveyor chain 6 products/services available

-

Bicycles, bicycle parts and accessories 2 products/services available

-

coupling 20 products/services available

- Industrial coupling

- Dotting the coupling

- Spiderflex coupling

- Pinflex coupling

- Crown pin coupling

- Tyreflex coupling

- Disc coupling

- Chainflex coupling

- Heavy-duty all-metal coupling

- Hydrastart coupling

- Spiderjaw and Spiderwrap connectors

- Renoldflex coupling

- High temperature blind coupling

- DCB GS coupling

- Frequency conversion coupling

- Public transportation coupling

- Universal joint coupling

- Standard gear coupling

- Flexible disc coupling

- Pin and bushing coupling

-

clutch 11 products/services available

-

Material handling machines and systems 1 products/services available

-

Elevator accessories 1 products/services available

-

zipper 1 products/services available

-

Fixtures and clamping equipment 1 products/services available

-

adapter 1 products/services available

-

Buckets, tanks and containers 1 products/services available

-

other products 12 Available products

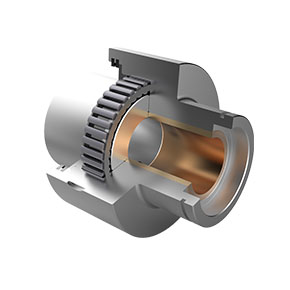

clutch

We provide the best product series: SA Sprag clutches, Sb Sprag clutches, SO Sprag clutches, SCPF and SCGF Sprag clutches and DM Sprag clutches.

SA wedge clutch

Features Suitable for all small machines requiring compact size. Grease lubrication and lifetime sealing. Provide reliability, maintenance-free. Size interchangeability with other leading clutch manufacturers. All SA series clutches can choose left-hand or right-hand applications. Light fan and blower printing Mechanical textile instrument, light pump, light general industrial application

Sb Sprag clutch

Features: An extended sleeve on one side allows direct installation of pinion gears, index arms, etc.-Design flexibility. Sleeve bearings in the extended sleeve-Higher strength and the same size as other manufacturers-Interchangeable SB3 clutch provides grease and life Sealing-No maintenance required. SB5 to SB16 clutches are available for oil or grease lubrication or without seals for oil bath applications. All SB series clutches are available for left or right hand applications: centrifugal pump, textile machinery, instrument, mixer, drive, blower and fan drive Light general industrial applications

SO Sprag clutch

Features All clutches are equipped with high-precision heavy-duty bearings, suitable for heavy-duty applications. Clutch sizes from 300 to 700 are equipped with ARO wedges to resist vibration and high transient torque and overload. SO series clutches, oil lubricated, suitable for overriding and backstop And medium indexing (up to 150 rpm) grease lubrication can be used for SO series clutches that require high inner ring overspeed or difficult to maintain. Grease lubrication is used for general overrunning and backstop applications SX series clutches. Oil lubrication is designed for medium to Heavy indexing applications (more than 150 indexes/minute) Applications: pump-driven, paper-making machinery, textile machinery, light-duty hammer mill, fan-driven, general industrial applications

SCPF and SCGF Sprag clutch

Features The combination of SO series clutch and Pinflex coupling allows angular, parallel and axial misalignment to absorb vibration and shock loads. The SO series clutch and two flexible semi-Gearflex couplings form a short cardan shaft, which can adapt to parallel and angular misalignment Flexible shaft connection for over-limit drive applications. Grease lubricated clutch is used as a standard for high overspeed and infrequent maintenance. Larger shaft size structures are allowed. Pinflex clutches use all-steel coupling halves for compactness and strength Gearflex clutches use all-steel dual-engagement couplings for maximum flexibility. Application limitations. Drive dual-drive systems-ultra-speed generator sets, packaging machinery, textile industry, fan drive, steel mills, mining industry, general industrial applications

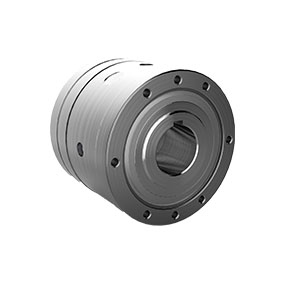

DM Sprag clutch

The DM series of direct-mounted wedge clutches are designed for use as a backstop in applications that require compact size.The clutch is designed to be installed in a housing with a shaft as the inner ring.This type is particularly suitable for gear devices and similar devices that ensure good concentricity between the shaft and the housing.Features High torque capacity and compact direct mounting design is suitable for backstop applications. The DM clutch is directly driven to the shaft. There is no inner ring, so the design is compact.The clutch is suitable for gears that provide lubrication with oil. Conveyor drive casting equipment drive steel mill textile machinery packaging machinery water treatment

SH wedge clutch

The Szp Group Sprag clutch stopper with a central torque arm is an independent device that can be installed at any time on the main shaft of an inclined conveyor or elevator or other suitable drive shaft to prevent backing.Features High-precision wedges produce instantaneous action through zero backlash. High-quality, high-precision heavy-duty bearings are suitable for demanding applications. SH clutches are designed for long life and lower overall operating costs. Large holes can be accommodated in a compact design (Up to 20") and high torque capacity interchangeable one-piece central torque arm design, easy to replace with other brands, quick disassembly mounting pins, quick disassembly of the torque arm enhanced labyrinth seal, suitable for harsh environments, grease or oil filling Option Axial fixing ring is suitable for all sizes of Szp Group Sprag. Clutch readjustment SERVICE TO NEW is suitable for all sizes. Typical applications. Inclined belt conveyor. Bucket elevator. If reverse rotation occurs, it will cause serious safety problems and may cause mechanical failure. In order to overcome the problem of drive reversal, the Szp Group Sprag Clutch block is installed on the main shaft of the conveyor and fixed on the block installed on the conveyor frame by a torque arm. Aggregate industry Szp Group SH Sprag Clutch Holdbacks are used worldwide Aggregate industry, usually combined with high-quality RENOLD gearboxes, usually used for inclined conveyors. SH Sprag Clutch Holdback is located at the end of the conveyor spindle. If the drive fails or stops when the conveyor belt is loaded, SH Sprag Clutch Holdback will immediately Prevent any reversing. This is because the wedge element of the clutch always keeps continuous contact with the inner and outer rings of the clutch element of the stopper. The resulting downtime and any potential risk of accidents to personnel are avoided. Szp Group SH Sprag Clutch Holdbacks are very suitable for the aggregate industry. They are equipped with high-quality seals to prevent contaminants from entering the internal parts and ensure a long device life. Mining Szp Group SH Sprag Clutch Holdbacks are installed on inclined conveyors and are used in all parts of the world Bulk materials are transported in many coal mines or iron ore mines. A typical mine application example is shown on the right. The SH Sprag Clutch Holdback with a central torque arm is installed on the drive of a plate feeder in an iron ore mining plant in Canada to prevent the drive If any reversal occurs, if the drive fails or stops. This is because the wedge element of the clutch always keeps continuous contact with the inner and outer rings of the clutch element of the stopper. The resulting downtime and any damage to personnel are avoided Potential accident risk. The high-quality components and overall robustness of the Szp Group SH Sprag Clutch Holdback with a central torque arm design are very suitable for the heavy and harsh environments where the plate feeder operates to ensure a long device life. Material handling Szp Group SH Sprag Clutch Holdb acks is installed on many inclined conveyors and bucket elevators that transport bulk handling materials around the steel plant, such as coking coal and iron ore, major docks, and transport bulk materials to warehouses and around the world Many other locations.

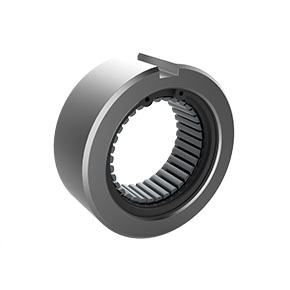

REGV roller clutch

Szp Group REGV series trap roller flywheels are self-centering through sliding bearings.Torque is transmitted to the inner ring through the key and to the outer ring through the torque arm.The shaft tolerance must be h6. The main purpose of the REGV flywheel is as a backstop.The flywheel should be fixed to the fuselage by placing brackets on either side of the torque arm or using pins or bolts in the groove.Please note that there needs to be a 1% slot width gap between the torque arm and the bracket or the slot and the pin.If bolts are used instead of pins, no axial load must be applied to the torque arm.Non-return screw pump/pump belt/bucket conveyor inclined conveyor escalator gear driven ventilator/fan Another application is indexing, where the push rod is connected to the torque arm slot.The gap between the groove and the pin must be 1% of the groove width. REGV is pre-filled with grease when supplied and usually does not require further sealing.Indexing metal stamping processing packaging machine indexing machine assembly machine printing machine

REUK roller clutch

The REUK series are flywheels that contain 62 series bearings.The self-centering flywheel has been greased and protected against dust.For the REUK model, transmission is achieved by mounting the inner ring on a shaft with a tolerance of n6.The outer ring is installed in a housing with N6 tolerance. The REUKC model is equipped with a keyway on the inner ring and should be installed on the k6 tolerance shaft.The outer ring is installed in a housing with N6 tolerance. REUKCC models are equipped with keyways on both the inner and outer rings.The inner ring is mounted on a shaft with a tolerance of n6.The outer ring is installed in a housing with H6 tolerance. The REUK2RS model is equipped with a waterproof seal. REUK series have built-in C5 gap, which becomes normal gap after keying.The seat ring can be glued to the shaft and seat.In this case, the gap remains C5.

REUS roller clutch

Szp Group REUS series trap roller flywheels are not self-centering.The bearing must be placed close to the flywheel to ensure concentricity between the inner ring and the outer ring. REUS series flywheels have the same external dimensions as standard 62 series bearings.Torque is transmitted to the inner ring through the key and outer ring through an interference fit.If the face key in the outer ring is used for torque transmission, the bearing housing tolerance should be H7 to provide a press fit.The enclosure must be strong enough to withstand the stress from interference.The shaft tolerance must be h6/j6.Before use, the flywheel must be lubricated.Oil lubrication is essential for over-run applications. REUS is an open design, so a seal must be provided during installation.

REGL roller clutch

The REGL F2-D2 (or D3) series includes a REGL basic unit flywheel, combined with an F2 fixed flange and a D2 (or D3) cover flange.Torque is transmitted from the shaft and the outer ring to the inner ring through the key through the bolt.The parts installed on the outer diameter of the outer ring should be drilled according to the H7 tolerance.The shaft tolerance must be h6/j6.The device comes with two paper gaskets for use between the outer ring and the sealing cover/fixing plate.Failure to use washers may result in loss of lubricant and subsequent rapid failure of the flywheel.Before use, the flywheel must be lubricated according to the instructions on page 35 of our current catalog. The REGL F2-D2 (or D3) device is a self-sealing design.If D3 type end caps are used, sealant must be applied to the keyway to avoid the loss of lubricating oil through the keyway.For pre-lubrication options, REGLG series can be used, please contact Szp Group sales for help.

Flywheel clutch

Szp Group has a wide range of flywheel clutches suitable for all overrunning, indexing and backstop applications.